[:ru]В современном мире человечество всегда стремится облегчить жизнедеятельность в помощью новейших технологий. Для этого начинают придумывать и разрабатывать «умные машины», которые быстро входят в обиход. Для проектирования моделей уже создали инженерные технологии, новейшее оборудование, переход чертежей из плоского рисунка в объемные реалистичные чертежи, назвали такую программу – BIM или ТИМ.

The main tasks of BIM for equipment manufacturers

First of all, you need to get acquainted with the software market and with the level of knowledge of the modeling project from rivals;

To study the essence of the program, what exactly it is used for, in order to weigh the purpose of BIM design and the business processes of the working organization.

The tasks of the company and this technology are one in their work, therefore they affect each other. The further work of innovation and architectural works depends on the tasks. The beginning is laid in the design, construction and verification work of modeling, and ends with numerous misunderstandings, disputes in attributes and engineering refinement.

An important detail is the analysis of the company's growth along with the program. It requires special attention and a clear understanding in its development. Once the start is made, it will be impossible to avoid the activation of the organization's business activities in building information modeling. The technology was created to begin the creation of engineering projects and their further development.

Features

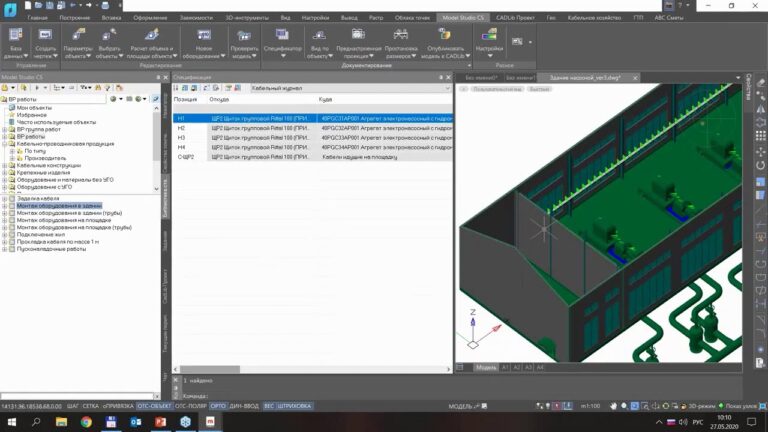

As an information product – BIM is aimed at creating and developing a specific product. This is a model that, in addition to a graphical image, provides basic data in the form of various elements of the structure and order processing functions – displays detailed information in a certain form.

The electronic image in the form of a graph is developed by the function of a graphic drawing, and for providing information – the level of initial information.

Advantages

- Striving to meet the state requirements of organizations. The Minister signed a document on the mandatory use of information modeling technologies. This gives many performers an advantage in convenience while working. After that, the program aims to become even simpler and more productive;

- Implementation of design on an ongoing basis. After a regular process of information modeling, the company has the opportunity to switch from mechanical activities to new technologies.

- The possibility of fast and high-quality use of the equipment. Old developments remain in the database, which can be viewed or restored. The manufacturer of the unique program took care of the safety of information, as well as its destruction and transfer, using USB drives;

- Improving the quality of production of graphic drawings.

С помощью информационного моделирования, появляется возможность в оперативном поиске недочетов и ошибок. Это помогает избежать дорогие строительные услуги в дальнейшем, после разработки проекта.[:en]В современном мире человечество всегда стремится облегчить жизнедеятельность в помощью новейших технологий. Для этого начинают придумывать и разрабатывать «умные машины», которые быстро входят в обиход. Для проектирования моделей уже создали инженерные технологии, новейшее оборудование, переход чертежей из плоского рисунка в объемные реалистичные чертежи, назвали такую программу – BIM или ТИМ.

The main tasks of BIM for equipment manufacturers

First of all, you need to get acquainted with the software market and with the level of knowledge of the modeling project from rivals;

To study the essence of the program, what exactly it is used for, in order to weigh the purpose of BIM design and the business processes of the working organization.

The tasks of the company and this technology are one in their work, therefore they affect each other. The further work of innovation and architectural works depends on the tasks. The beginning is laid in the design, construction and verification work of modeling, and ends with numerous misunderstandings, disputes in attributes and engineering refinement.

An important detail is the analysis of the company's growth along with the program. It requires special attention and a clear understanding in its development. Once the start is made, it will be impossible to avoid the activation of the organization's business activities in building information modeling. The technology was created to begin the creation of engineering projects and their further development.

Features

As an information product – BIM is aimed at creating and developing a specific product. This is a model that, in addition to a graphical image, provides basic data in the form of various elements of the structure and order processing functions – displays detailed information in a certain form.

The electronic image in the form of a graph is developed by the function of a graphic drawing, and for providing information – the level of initial information.

Advantages

- Striving to meet the state requirements of organizations. The Minister signed a document on the mandatory use of information modeling technologies. This gives many performers an advantage in convenience while working. After that, the program aims to become even simpler and more productive;

- Implementation of design on an ongoing basis. After a regular process of information modeling, the company has the opportunity to switch from mechanical activities to new technologies.

- The possibility of fast and high-quality use of the equipment. Old developments remain in the database, which can be viewed or restored. The manufacturer of the unique program took care of the safety of information, as well as its destruction and transfer, using USB drives;

- Improving the quality of production of graphic drawings.

С помощью информационного моделирования, появляется возможность в оперативном поиске недочетов и ошибок. Это помогает избежать дорогие строительные услуги в дальнейшем, после разработки проекта.[:]